Our Services and Capabilities

Newbec excels in assisting our customers to achieve their ultimate goals, whether it would be their own objectives or final end user goals.

MACHINING

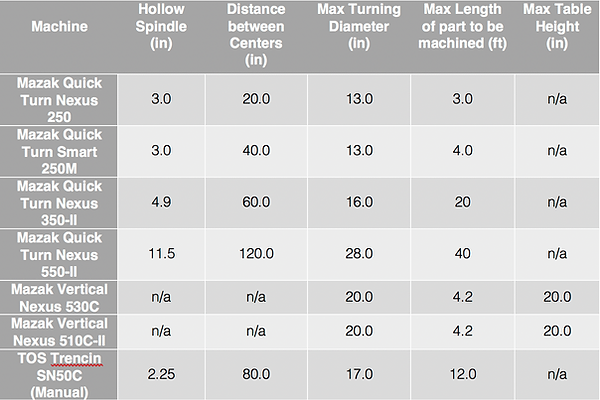

TURNING

At an average of 16 years of experience per machinist, the turning department is capable and consistent.

Four Mazak lathes with capacity for:

-

Outside diameter up to 28 inches

-

Overall length up to 40 feet

-

Maximum hollow spindle of 11.25 inches

MILLING

The milling department boasts 30+ years of experience and operates two Mazak mills equipped with a fourth axis.

CAPABILITIES

Our experienced team includes over 30 years of downhole tool design and engineering, along with accomplished quality assurance personnel and an exceptional leadership team.

Newbec can supply all materials including alloy steels, austenitic, martensitic and non-mag stainless steels. Other metals include aluminum, bronze alloys and copper alloys. Further, Newbec can procure other specialty materials such as PTFE, polyether (Peek), elastomers and other thermoplastics. Newbec can manufacture parts and components to API and DS-1standards.

SURFACE TREATMENTS

The capability to perform surface treatments in-house highly contributes to excellent on-time delivery and better quality monitoring.

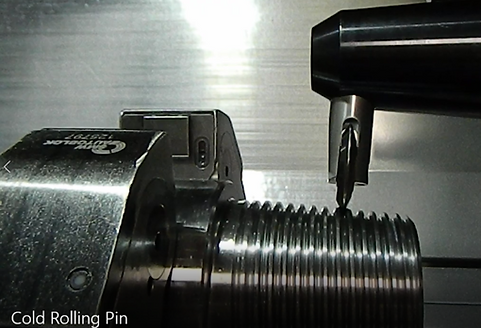

THREADING

Cold (or root) rolling is a process shown to improve fatigue life in thread connections. Along with cold rolling, Newbec is proudly partnered with a network of licensed premium thread manufacturers to deliver the highest quality in threads and final products.

INSPECTION

Newbec is equipped with a wide variety of calibrated measuring equipment and gauges including API, ACME, UN and NPT. The ability to perform dimensional and surface finish inspection in-house complements our full-service quality objectives.

NDE INSPECTION

Newbec offers the capability to perform MPI and LPI inspection in-house. This allows us to better control delivery times to our customers.

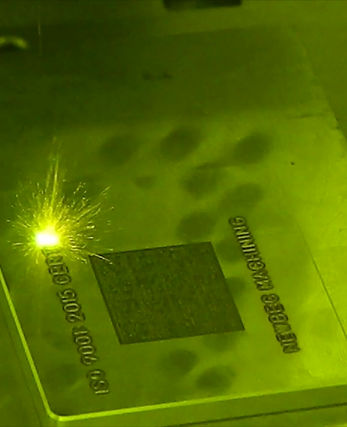

PART IDENTIFICATION

Newbec can appropriately identify parts and components for proper identification depending on part size and material.

Newbec offers the following processes:

-

Scribing

-

Stamping

-

Low-Stress DOT peening

-

Stationary and Mobile equipment

-

-

Laser Marking

-

2D Bar-Coding

QUALITY ASSURANCE

Quality is the pinnacle of Newbec and we are proud to offer the best in quality assurance. The quality management system at Newbec is built to exceed industry standards. Newbec guarantees the quality of every manufactured part but also offers quality assurance as a service